- Homepage

- >

- Scientists

- >

- GANIL-SPIRAL 2 facilities

- >

- Target laboratory

- >

- Target laboratory

- Accelerators

- Available beams

- Experimental areas

- ARIBE

- D1

- D2

- D3-D6 / LISE

- D5

- DESIR

- G1 / VAMOS

- G2

- G3

- G4

- IRRSUD

- LIRAT

- NFS – Neutrons for Science

- S3 – Super Separator Spectrometer

- Instrumentation

- ACTAR TPC

- AGATA

- CHATEAU DE CRISTAL

- DIAMANT

- EXOGAM / EXOGAM2

- FAZIA

- INDRA

- LPCTrap

- MORA

- MUST2

- NEDA

- PARIS

- REGLIS3

- S3 Low Energy Branch

- SIRIUS

- Target laboratory

Target laboratory

The Target Laboratory is dedicated to the development and production of targets tailored for experiments using heavy-ion beams. These targets are designed primarily for GANIL users but can also support experiments conducted outside the laboratory. Depending on the requirements and the type of studies, various fabrication methods are available, including Physical Vapor Deposition (PVD), sublimation, rolling, molecular plating, and polymerization. The choice of method depends on the specific characteristics required, e.g., the target thickness, as well as the properties of the deposited material. Carbon films, used either as strippers or as backing materials for targets, are also available. Depending on their purpose, targets may be self-supporting or mounted on backing substrates.

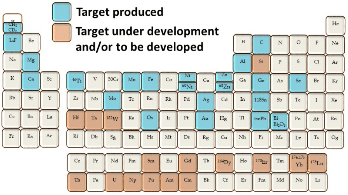

The list below provides examples of targets that are regularly produced, as well as those occasionally fabricated based on specific requests.

Backing/ self supported

Backing material

Thickness (µg/cm²)

Metal-Oxide…

Equipement

- 12T manual press for pellets or powder mixture preparation

- E-beam deposition : Modèle de l’appareil ou autre détails ?

One electrostatically focussed electrons system heating a crucible for oxide material to reduce and evaporate them as metallic form;

One electron gun system (3 to 6 kw) heating directly the material in a cooled crucible for highmelting point material because they are highly reactive at elevated temperature; - Rolling machines : 2 cold rolling mills: one manual and one motorized placed in a glove box to work under inert atmosphere for thick foils production used as backings or targets;

- One thermal resistance heating of high-purity carbon rods (3 mm diameter, 75 mm length) for large carbon foils (20*20 cm²; 10-70 µg/cm²);

- 2 resistive heating of crucibles or boats for thermal evaporation of metallic, low melting point materials, one dedicated to isotopically material for targets and one to natural material for metallisation of foils for detectors;

- Chemistry equipment

A heating plate and auxiliary equipment for large –(CH)2- or –(CD)2- targets made by polymerisation;

An electro-deposition cell, i.e. used for osmium targets - Characterization : Spectromètre à fluorescence X (XRF)