- Homepage

- >

- Industry

- >

- Applications with ion beams

- >

- IRRADIATION OF MATERIALS

- FACILITIES

- IRRADIATION OF ELECTRONIC COMPONENTS

- IRRADIATION OF POLYMERIC MEMBRANES

- RADIATION BIOLOGY

- IRRADIATION OF MATERIALS

- ACCESS CONDITIOPNS & FINANCIAL CHARGES

- RADNEXT TNA

- CONTACT

IRRADIATION OF MATERIALS

Materials can be irradiated under different physical forms, be they liquids, solids or gases. As for solids, they can be irradiated either as slabs, powders or thin films.

Almost all the beams delivered by the GANIL facility are available for these applications. According to the samples thickness or the necessity for in-situ analyses, either the IRASME or the IRRABAT line of the D1 cave is applicable. IRASME is more adapted for in-situ analyses of thin samples whereas IRRABAT is indicated for thick samples or irradiations in sealed ampoules (glass or other materials). In both lines, irradiations can be performed under controlled atmospheres (O2, air, inert gaz or vacuum) at room temperature.

In-situ analyses can be performed using mostly spectroscopy: Infrared, Mass (up to 200 amu), or UV-Visible. Irradiation temperatures for in-situ UV-Visible and FTIR analyses range from 11 K to 298 K for small samples (13 mm diameter maximum).

The beams most used until now are 13C-20Ne 13.7 MeV/A and 36Ar 95 MeV/A associated to the electronuclear energy applications (Bitumen, Polymers, and nuclear waste immobilization matrices); for simulating alpha irradiations

Maximum surface. Bands of 5cm width and 10 cm length

The CASIMIR set-up installed on the IRASME line in the D1 cave

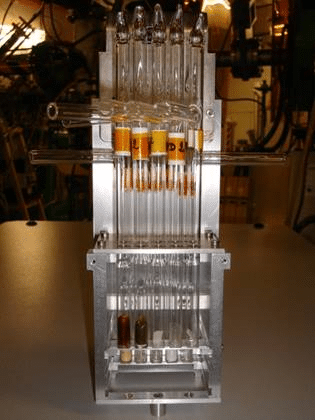

Sealed ampoules containing polymers installed in the sample holder that can bear up to 13 ampoules.

Local Points of Contact:

- Eloïse Dessay for beam time requests

- Yvette Ngono (Yvette.ngono@ganil.fr, 0231454751) for experiment preparazion and coordination